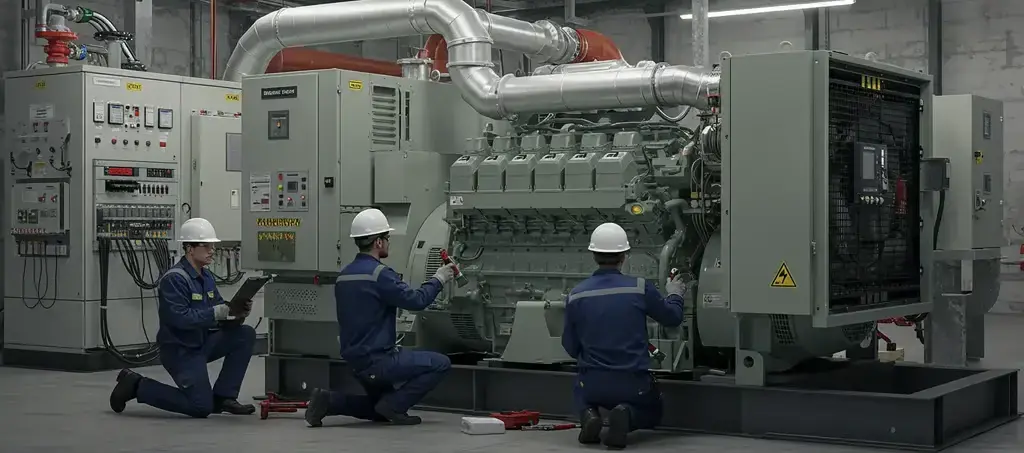

Industrial Maintenance

Reliable, professional, and built to keep your operation running at peak performance

At Techreliant we deliver complete industrial maintenance solutions tailored to the needs of modern facilities.

1. Corrective Maintenance

Quick, efficient repair of unexpected equipment failures.

We diagnose issues fast and restore your machinery to full operation to minimize production downtime.

2. Preventive Maintenance

Scheduled maintenance that prevents breakdowns before they happen.

Includes:

Routine inspections

- Lubrication

- Calibration

- Component replacement

- Safety and performance checks

Division A: Mechanical Engineering Services

Rotating Equipment & Systems

Division B: Electrical & Instrumentation Services

Power Systems & Control Solutions

Emergency Support

Rapid response for urgent mechanical or electrical issues to keep your facility running with minimal disruptions